If you are new to homebrewing, you have probably never even heard of a RIMS system, let alone considered building your own custom style.

But as you progress on your homebrewing adventure and start paying more attention to every meticulous detail of the brewing process, you will probably want to employ some form of mash recirculation system like a RIMS or HERMS brewing equipment system.

So, are you still wondering what the heck a RIMS brewing system is? If so, read on! It’s just one of two methods of using brewing equipment to recirculate your mash during the brewing process.

We compare it with the other system, HERMS in another post which you can find here, but in this post, we look at what exactly is a RIMS system, why you need one, and then embrace the inner engineer in all of us with details of how I built my own RIMS system.

If I don’t make my first million writing about it, who knows, I may go into building the systems and selling them to others. It’s relatively easy and very effective!

What Is a RIMS System?

First pioneered by Rodney Morris in 1992, the RIMS concept is a Recirculating Infusion Mash System. ‘Recirculating what?’ I hear you ask. If you were ever to remove a quart or two of wort during your mash, then that would be recirculating your mash.

Unfortunately, once your brewing system gets to about 10 gallons (38 L) in size, it can become difficult to move larger 100 lb (45 kg) pots full of hot wort about, so many brewers would use a pump to transfer the wort instead. This same pump can then be used to recirculate the wort through the mash.

Using a pump with a heater and precision temperature controller, the first RIMS essentially pumped the wort over a heated element and was then returned to the mash, which maintained a constant temperature.

Every all-grain brewer likes to recirculate the wort at the end of the mash, as this helps clarify the wort and removes all the particles of grain, both large and small, from the sweet wort before moving to the boiling stage.

If you were to remove some of the mash from the bottom of your mash tun and then heat it to 158ºF before returning it to raise the lower temperature, then you would basically be doing the same job as a RIMS but manually.

Why Not Stick With a Single Infusion Mash?

Many brewers, especially when first starting out in all-grain brewing, will use a single infusion mash where they just recirculate the wort at the end of the mash period. Usually made with some kind of cooler with a filter screen or tubes added, the brewer creates an insulated mash tun.

A Brew-in-a-Bag (BIAB) system is also another popular option for first-time all-grain brewers. Both are relatively simple ways to perform a mash and are inexpensive too. A cooler-based system helps retain the heat while with a BIAB allows you to apply heat directly to the kettle without fear of scorching the grains.

The problem with both these methods of single-step infusion mashing is when you start to work with larger brews, especially 10 gallons or more.

While it is easy to transfer just 5 or 6 gallons of wort by dumping or siphoning it into a boiling pot or into another mash tun, brewing large quantities such as 10, 15 or 20 gallons of hot wort can be very awkward and difficult.

Lifting a 10lb bag of grain might be manageable, but any larger, especially when it has been steeping for an hour, can also be difficult. As well, it can be difficult to find coolers that are large enough to support these larger batches of beer.

The Advantages of a Recirculating Mash System

The problem of keeping a mash at a constant temperature for mash periods that may range from 60 – 90 minutes becomes even more apparent when using a 15 – 20 gallon stainless steel mash tun.

Most stainless steel brewing vessels aren’t insulated and will conduct heat relatively well. The simple technique of heating an infusion and letting it sit in a cooler used for smaller batches may not work, as well in a large stainless pot or a converted keg.

The other problem with larger batches of wort is the possibility of hot and cool spots in the mash developing over time, making it difficult to maintain a consistent temperature over the entire grain bed.

The recirculating mash systems address both of these issues by using a pump that not only moves the wort and recirculates it to avoid hot spots, but also passes over a heated element to maintain a more consistent temperature throughout the entire wort.

Typically, a precision temperature controller will switch the heating element in the pump line on and off to maintain a constant mash temperature.

It’s not just about the size of your mash when you use a mash recirculation system, as they can also offer the following advantages:

- Constantly recirculating the wort through your grain bed ends up with a much clearer wort than you would get from a manual siphoning or dumping of the wort known as a Vorlauf (the German term for “first runnings”). Although there is very little empirical evidence to support the benefits of a clearer wort, it just seems obvious that a clear wort going into a boil kettle is better than a cloudy one.

- The mash temperature is controlled with more precision, with the wort being constantly recirculated, ensuring mash efficiency and maximum enzyme utilization. With better temperature control, you are more likely to get the exact same wort you planned for when designing a recipe. When using a cooler as your mash tun, there may be a 3 or 4-degree temperature fluctuation, and it’s more difficult to control which enzymes are working on your beer.

- The repeatability of a recipe is one of the main reasons a brewer may choose to use a mash recirculation system. Every brewer at some stage in their homebrew adventure, especially as they get more advanced, will design a recipe and make a beer or series of beers that becomes their favorite. being able to tweak those recipes and get predictable results is much easier with the control you get from a mash redistribution system. It’s also easier to get consistent results. For smaller microbreweries that may be using a home-based system as a pilot scheme, repeatability is of the utmost importance.

- Another benefit of a recirculating mash system like RIMS is you can perform more complex mash schedules. Although single infusion mashes may work for most homebrewers, especially those new to all-grain brewing, there may come a time when you want to perform a more complicated mash schedule. A RIMS system allows you to easily step through all the required temperature stops with very little extra effort. No more adding infusions of boiling water or removing a part of the mash and reboiling it to raise the mash temperature to the next step.

Why Should You Build Your Own RIMS Brewing System?

Although both RIMS and HERMS are advanced homebrew systems that many homebrewers won’t ever touch, the fact you are still reading suggests you are interested in investing in a Mash recirculation system.

However, unless you have very deep pockets, a decent RIMS or HERMS brewing setup can be very expensive to buy. Think about the expense of next year’s holiday to Vegas, and you’re maybe halfway there!

In general, a RIMS system will be easier to construct than a HERMES, as it requires fewer parts and should be within the reach of most brewers who have basic DIY skills (welding skills would also be useful).

Just a quick warning – the project does involve electricity. So, if you aren’t too comfortable playing around with potentially lethal voltages, then don’t. You can also get help from a willing electrician buddy.

The parts you will need to construct your own RIMS system are also quite easy to get hold of. Most of the metal pipes, valves, electrical cables, and elements can be purchased locally at your nearby DIY store or even from a homebrew depot.

Or, if you decide you can wait a couple of days, there are also many online retailers that sell the equipment and spare parts you need.

Here is a partial list of some of the online vendors I used:

- ProflowDynamics.com for 1/2 Cam and Groove (Camlock) Stainless steel Fittings.

- Morebeer.com for Sanitray Try Clamp fittings and an SS Brewtech Domed false bottom

- Pex Supply.com for LP Orifice Pilot Burners

- ApexControls.com for a Honeywell Ignition system kit

- eBay.com for various Swagelok fittings, Stainless ball valves, Rigid tube bender for Stainless Steel, etc…

- onlinemetals.com tends to have the cheapest prices for stainless steel tubing

- Agrisuply.com for Banjo Burners and orfifices

- Castorcity.com for castors formy RIMS Build Brew Stand

Although some of the part names may look strange at the moment, all will become clear as I detail my RIMS to build this project below.

Why Did I Decide to Construct My Own RIMS?

One of the main reasons I decided to build my own RIMS was not being able to find a RIMS brewing system that suited my needs.

After looking at a few commercial systems on the internet, I found that I liked the Sabco Brew Magic the best. However, that system only had one pump and the boil kettle was gravity fed from the mash tun.

Therefore, I had to come up with a more complicated RIMS Plumbing design.

The other thing that is different from many systems is the chiller setup. I heard some bad things about infections caused by plate chillers and the difficulty in cleaning them (of which the Blichmann Therminator is the most widely recognized).

So, I decided to go with an immersion chiller set-up and run ice water from my HLT (Hot Liquor Tank) through the IC (immersion chiller) and circulate it with one of the pumps while whirlpooling with the other.

This setup has several advantages, such as the following:

- The wort doesn’t have to go through an external device to get chilled as it would in a counter-flow chiller, a HERMS set-up, or a plate chiller.

- Only water is run through the chiller so it will be easy to clean, drain, and dry.

- It’s easy to sanitize. Just put the IC into the boiling wort 15 minutes prior to the end of the boil.

- I can run water from my filter housing and back-flush the IC with tap water to get the wort temp down before using the ice water. I just have to put in the hose in the outline and close a valve on the HLT.

- The IC set-up was cheap because I already had the chiller.

Again, the cost was a major deciding factor. A system like the one I built was $6000 but could easily retail for between $15 -20K. Also, I now have the satisfaction of having built my own advanced system, which improves the repeatability of my favorite recipes and the control over my brew.

This system is the envy of my local homebrew club and I’m in good company as many of the better-known microbreweries like Sierra Nevada started with a similar home-constructed advanced brewing system.

How To Build Your Own RIMS Advanced Brewing System

The Ultimate DIY Project: I purchased a stainless steel brew stand from a guy in Florida not long ago. He put it on eBay but didn’t want to have to ship it anywhere. I basically let the auction end, then got ahold of him to see if he’d sell it offline.

I didn’t have anything to go by when I designed my system, so maybe some of you will find this helpful. The plumbing is done in all 1/2″ OD stainless tubing with Swagelok or “Swagelok Type” fittings.

The problems so far usually entail little things, like not having all the right small fittings and having to run to town to purchase them (nipples, adapters, elbows, etc.).

I’m using stainless steel fittings wherever possible. They are usually more expensive, but worth it in the long run, because stainless steel is extremely durable (almost indestructible) food-grade metal that resists corrosion in caustic fluids and can be sanitized easily making it basically food-grade.

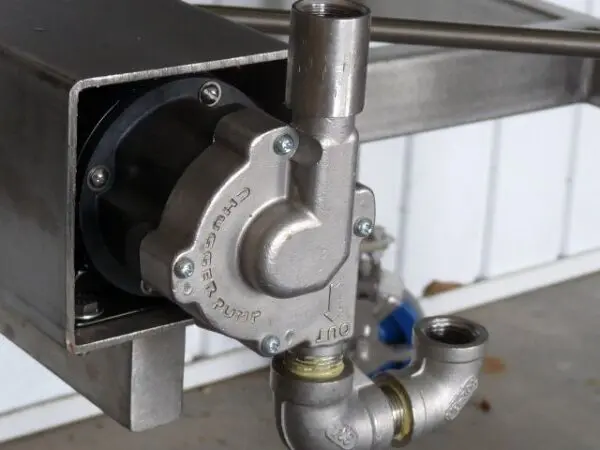

I’ve wanted to use March Pumps with Stainless Steel heads but the price was way too high, until now.

Northern Brewer has their own Northern Brewer Wort Pump at a great price point. The stainless steel head is an option and only adds about $25. Just click on the “Head Option” to select Stainless Steel.

OK, on to the RIMS System build again. One of the next steps is to connect the gas valves with the burners and I haven’t really decided whether to go with a flex hose or make the lines with stainless tubing and bend the tubing.

If I go with tubing, I’ll have to find a way to flare the 1/2″ tubing for the orifice on the burner. With a flex gas connector, it will come ready with female flare fittings and the hose can be bent in any configuration. It’s a good temporary fix and I think it’s the way I’ll go.

Next will be to run the 1/4″ pilot tubing and attach the Honeywell pilot light and flame sensor to the stand and into the burner. The ignition control module will maintain the burner when a call for heat is detected, and preserve the pilot light flame.

If it senses the light has been blown out, it will shut down the burner and try to relight the pilot light. This is all for safety and I think a very good idea, as I plan on using the stand for demonstrations and wouldn’t want anyone getting hurt while no one is watching the pilot.

I had to find a way to go from the 3/8″ male flare orifice fitting on the burners to my stainless tubing. Here is what I decided to do:

I found this “3/8″ x 3/8″ female flare coupling union”. The female flare fitting will fit on the end of the orifice valve and convert to 3/8″ MPT. I’ll then get a 1/2″x3/8″ stainless 90° Elbow, to which I’ll put my Swagelok 1/2″ MPT x 1/2″ Tube union and go on with the stainless tubing to the Gas Control Valve.

The stainless elbow will save me from having to bend the stainless tubing as it goes into the burner.

The whole point of the fitting from CHI Company was to keep from having to flare the stainless tubing, which is extremely difficult without a high-dollar flaring tool. The ones for copper won’t work on stainless tubing.

While waiting on parts for my RIMS Build, i.e., the stainless pump heads and the female flare adapter, I decided to work on my kegs. I learned a big lesson when cutting the top of the keg for the lids – use a calculator.

I made a math error in my head and ended up cutting the holes too small. I bought 12″ glass lids from PotsandPans.com that fit an Anolon pot.

The ID of the lids is 11.75.″ I made a jig for my grinder using a 2″ hole saw as the pivot point (it fits perfectly in the center hole on a keg) for the jig which holds (clamped) my grinder vertically. Here is a YouTube video showing you how it’s done.

The first cut was pretty rough, but the second, shown here, was much nicer. After cutting the holes for the lids (and making the calculation error), I found out the lids didn’t fit.

In retrospect, I should have tried one lid on the first keg, then I could have corrected the mistake and only had one keg with the cutout too small.

What I decided to do was to send the two lids back and order smaller lids. My calculation error left me with a 10.75″ diameter opening instead of the 11.75″ I needed. The lids were for a 12″ pot, so I figured I’d order an 11″ lid and hope it has the 1/4″ lip.

The people at PotsandPans.com were super nice and I don’t even have to pay shipping back on the new lids. I did have to pay $18.50 Priority Mail shipping to send the 12″ lids back.

I don’t know how they could have sent the two lids in separate boxes via Priority Mail and only charged me $5 shipping. What a deal! UPDATE: I got in the new lids. I’ll have to do some grinding to get them to fit, but much less than if I’d kept the 12″ lids.

I went to the HomeBrewTalk.com forum and found the thread on how to polish a keg. I went to Lowe’s and purchased three grits of Gator brand metal finishing discs (fine, medium, and coarse) and a backing attachment for my angle grinder.

I started with the coarse grit and went over the entire keg, and then moved on to the medium and finally the fine grit pads. Talk about back-breaking and time-consuming work.

I also bought a set of polishing pads, which I will use with a polishing compound to finish the kegs. They should end up looking like chrome. Why have a showpiece brewery and not do the extra work to make the kegs look great?

Here are a few more pics of my RIMS Build that I took after I finished working on the kegs for hours and hours. What sticks out like a sore thumb is how small my 12.75-gallon kettle is. I think I’ll have to order one of these 26-gallon Stainless Brew Kettles from MoreBeer.com.

RIMS Build Vendor List (Partial)

Building a RIMS system can be very rewarding, but you have to make good decisions for your vendors to reduce costs while keeping the quality high.

Here is a partial list of vendors that I used for my RIMS build:

- ½” Cam and Groove Stainless Steel fittings. From ProFlow Dynamics.com.

- Sanitary Tri-Clamp fittings from MoreBeer.com: 1.5” Tri-Clamps, Stainless Steel

- LP Orifice Pilot Burner for natural gas, at Pex Supply.com.

- Weldless fittings for keg, i.e., Sight glass, bulkhead, silicone tubing, thermometers… at Bargain fittings.com.

- The Honeywell electronic ignition retrofit kit includes (but is not pictured) a VR8204A2142 gas valve with a 1/2 inch by 1/2 inch inlet/outlet, the ignition module, and a wiring harness. The pilot pictured is not used, so order from Pex as above. The Y8610U4001 Electronic Ignition System by Honeywell is a complete kit converting a conventional standing pilot system to an intermittent pilot system. For use with 24 Vac gas-fired atmospheric furnaces, boilers, and heating appliances.

from Apex Controls.com. - Ss Brewtech Domed False Bottom from MoreBeer.com

- All the various Swagelok fittings, ie. ½” Tube x ½” MPT unions, tees, stainless ball valves, Ridgid tubing benders for SS, etc. were found on eBay.

- The cheapest price for stainless tubing is at onlinemetals.com.

- 10” High-Pressure Hurricane burner Replacement From Agrisupply.com.

- Castors for my RIMS Build Brew Stand.

Here is my solution to the problem of where to mount the ignition modules for the gas control valves and intermittent pilot lights. The electronics in the modules would cause interference if mounted in the control panel, and they also need to be protected from water and spills.

I looked around for stainless boxes and many were just too expensive. The ones on eBay that had gaskets and were made for electrical devices were called “enclosures” and were made by Hoffman. These ran anywhere from $50 to $450.

My solution was to get a 50-caliber ammo box. I plan on mounting it on the bottom brace between the pumps and close to the gas valves. It will be far enough from the heat to be safe, they seal with a waterproof seal, and when it’s painted silver, it will match the Brew Stand.

Here is a picture of one I just painted. I’ll post another picture when I have it mounted.

I installed the HONEYWELL Q345A1313 I.P. Pilot Burners on the brew stand. These need to be close to the burners with the pilot light “shield” aimed at the burner. I will install the LP orifice to run the pilots on Propane when I plumb the gas and spark plug wires.

I’ve seen people install them on a homemade angle bracket in the middle of the burner. However, I couldn’t find any suitable material for the brackets, so I used the brackets that came with the pilots and installed them up against the outside of the burners.

Here are a couple of picturess of the installation.

I purchased a new brew kettle from MoreBeer.com. I ordered it with a notched lid for my Immersion Chiller, which I plan to use to chill the wort down. This is one super-heavy-duty kettle and a great deal.

Plus, you get the MoreBeer customer service if you ever have any problems or need modifications made to the kettle. I have installed the Tri-clover clamps on all vessels, ball valves, and thermometers. Checking for leaks was a chore, though, but all are sealed tightly and ready to brew.

I still have to drill a few holes in the vessels. One return line on the HLT, a return line/Blichmann Auto Sparge on the MLT, and a return line for the whirlpool and drain line for the Blichmann Hop Blocker on the brew kettle.

I will wait until I get the stainless plumbing run before I decide where to drill the final holes.

I still have to fabricate the whirlpool arm to go on the Immersion Chiller, but I bought a small roll of 3/8″ OD soft copper from Lowes the other day, which should be a simple matter.

Here is a picture of the ignition modules for the intermittent pilot lights and dual gas valves. After doing some reading on HomebrewTalk.com, I found out that these modules could cause some interference if mounted in the same box as the other electronics.

So, here is my workaround. Stainless boxes were extremely expensive, and I couldn’t find one with the right dimensions.

The 50 cal ammo box was painted silver to match the rest of the stainless steel on the RIMS. The box was mounted on the lower brace in the center of the gas valves to minimize the wiring problems.

I drilled a couple of holes in the back for all the wiring to exit, and I plan on either sealing it with silicone or getting some large rubber grommets to prevent the wiring from rubbing on the sharp edges of the holes.

The ammo box is completely waterproof when sealed, and the holes are in such a position that they shouldn’t allow any liquids into the box (when properly sealed with silicone).

Here is another pic of the ammo box mounted and closed. I wish I could have found/afforded a stainless box that was waterproof, but this is a pretty good alternative.

You can get stainless steel pump heads or a pump with a stainless pump head installed at MoreBeer.com.

The stainless heads look much better and the footprint is smaller compared to the center outlet polysulfone heads I had on before. Talk about a nice upgrade!

I plumbed in the pilot lines and the gas lines to the burners. I bought a new RIGID stainless steel tubing bender but I didn’t end up needing it.

The RIGID models made for copper worked just fine. Besides, these have a tighter bend radius, so I have more control over the bends. It was all a lot easier than I imagined, however, I did go through a learning curve and learned to pay attention to the bends.

I made several mistakes on the 1/4″ pilot tubing. Several bends mysteriously went the wrong direction, so make sure to triple-check before bending.

Here is a shot of the wiring on one of the gas control valves. I purchased some generic spark plug wires from Auto Zone and connected them to the pilot ignitor. I then tie-wrapped them along the 1/4″ stainless pilot tubing.

The wiring harness to the ignition modules was also connected to the gas control valve and the rest was run into the back of the ammo box, which houses the ignition modules.

I did this on all three gas control valves. It’s not pretty yet, but I plan on getting a product called Bentley-Harris ConvoShield. It’s chrome and will withstand temps of 500°F. It should make the jumble of wires look much nicer. Here is a link to the website where I found the wire loom product.

I also purchased some chrome-colored tie-wraps meant to keep wiring looking nice inside of an engine that’s all chromed out. You can find them at Speed Shops or Cycle accessory shops online. Just Google Chrome Cable Ties.

Here is a pic of the burner hardware. I finally figured out how to adapt the orifice valve so it wouldn’t stick out so far. It took a LOT of searching, but I found a 3/8″ brass street elbow that fits into the hurricane burner.

The orifice valve screwed right into the elbow and everything is nice and snug now. I’m not 100% sure about how the orifice being up against the back of the 90° elbow will affect the flow of propane, but I can always cut off some of the orifices if need be.

This is a picture of the HLT burner with the 1/2″ stainless tubing running to the gas control valve.

You can see the pilot light tubing with the wires (these will be run to the control panel) wrapped around the spark plug wire and 1/4″ tubing. Also in the shot is the stainless heads I just installed.

Now, notice the bug screens on the burners. Around here we have a big problem with wasps making mud nests in anything with a hole. I had mud nests at the end of each stainless tube I had purchased for the plumbing build. I had to cut off about 3 inches to get them out.

Next, connect the wiring inside the Ammo Box to the ignition modules. The loose wires you see near the gas control valves will be connected and run to the control panel for 24V power and also connected to the Love Controllers.

Purge Valve Plumbed Inline

A stainless tee with the purge valve on top was fitted. The bottom fitting is a 1/2″ MIP x 1/4″ Compression fitting that will hold the 1/4″ Love temperature probe. I took the ferrules out of the fitting and will use o-rings to seal the probe from the wort. The ball valve will isolate the MT and BK from pump 2.

A second purge valve will purge the air out of the line for pump #1. There is also a stub-up for the “out” line on the immersion chiller. I have put 1/2″ stainless cam-locks on these to reduce cost and keep these lines airtight when the IC isn’t in the boil kettle.

RIMS Build – Install Blichmann AutoSparge

The Mash Tun has a Blichmann AutoSparge installed. The AutoSparge will add sparge water to the top of the grain bed and keep a pre-set amount of water above the grain to keep it floating.

It will also act as the wort return line while recirculating the wort during the mash. The black foam “float” will keep the silicone line just at the surface of the wort and the pump will add the wort gently to the top of the grain bed.

I set up the Immersion Chiller (IC) lines with Cam-Lock fittings because they were much cheaper and a lot smaller and lighter than the tri-clover clamps.

I have 1/2″ silicone lines fitted to the IC with male Cam-Lock fittings on the other end. When not in the boil kettle, the female Cam-locks have male plugs which are hanging nearby on ball-type chains (similar to an old-fashioned sink stopper).

The seals will allow me to design the system so that I don’t need to put ball valves on the lines. As long as the plugs are in place, that line is dead and is bypassed.

How I Installed the Ignition Modules in Ammo Box

So, now comes the fun part – wiring the control panel. Once that’s finished, it’s time to test it. Everything has to be water-tight and the propane side needs to be leak-free and working.

There are some adjustments that may need to be made to the gas valves and pilot lights/ignitors. For one thing, I’m not sure that the spark plug wires I purchased will work. I had to cut off one end and found that the core was not wire but carbon-impregnated nylon string.

So, I’m not sure that the connection I made there will carry the spark from the ignition module to the ignitor/pilot lights on the burners. I have to wait until I get the control panel wired to see if they work.

To have my control panel wired (pictures later). I purchased some flame retardant chrome wire conduit from O’Reilly Auto Parts for $15.99 each per 4′ of 3/4″ conduit and 8′ of 3/8″ conduit.

The conduit gives the stand a “polished” look. I also purchased some chrome tie wraps to attach the conduit to the stand.

I wanted to show everyone what my sight glasses look like after calibrating them with water. I fetched an empty milk jug and “tared” it on my postal scale to zero the measurements.

Afterward, I added enough water to weigh exactly 8 lbs 5.44 ounces (which I figured equals 8.34 pounds per gallon (ppg), or the weight of one gallon of water.

I made a mark around the top of the jug where the waterline was, then began filling up the keggle with water. It took 4 gallons before the water showed up in the sight glass, so that was the first calibration mark present.

If you would like to purchase these vinyl calibration numbers from BrewHardware.com, click here. I also purchased a couple of nickel-plated hangers at Wally World on-sale. These are the hangers from 3M that enable you to remove them by pulling on the tab of the two-sided stick-on tape. I figured I would use them to hang my power cord on.

RIMS Build – Problems

I ran into a few problems while doing the initial testing of the stand, specifically, the burners and gas valves. I believe one problem is that I need to increase the gas to one of my pilots. I had to return one pilot light assy.

Because it wouldn’t sense the flame, it just kept “sparking” through the pilot flame, so the gas valve never turned on the main gas to the burner.

The problem may lie in a connection to the ignition module, however, since this is the Robertshaw model 712-008 Retrofit kit. The other two are Honeywells and they seem to be working fine.

I did run into an immediate problem with the one burner that was working well. There was a casting defect in the side of one of the “spokes” of the Hurricane Burner. I don’t know how I missed it, but my flames were yellow for no reason. I turned off the gas and looked at the burner, and there was a small flame coming out of the “casting defect.”

Hurricane Product’s customer service was awesome. Even though I wasn’t the original buyer of the burner, and had no receipt, they said that they would send out a new burner right away. Now that’s what I call standing behind their products.

I also had to re-plumb the orifice valve (jet) going into my burners. Instead of pushing propane into the venturi of the burner, it was escaping out the vent holes in the rear.

So, I put the low-pressure orifice valves directly into the burners. After a trip to the hardware store, I re-worked the gas lines by adding a stainless coupling to the Swagelok 1/2″ compression fitting and adding a 1/2″ elbow with a couple of close nipples. It’s not as pretty but works like a charm.

I have almost all the bugs worked out now. I received the new burner from Hurricane Products and installed it. The pilot ignitor/sensor is still not here but should arrive in a couple of days. Some lessons learned are as follows:

- If the pump inlet fitting is 1/2″, use 1/2″ tubing and fittings. I used 1/2″ OD which is very small. One of my pumps sometimes cavitates due to a lack of fluid because the lines are so small. I have to shut off the discharge and slowly open it up until I get the flow I need.

- Two identical gas valves can output different levels of flames on the main burner. I had to drill out the orifice on my MT burner to get more propane and better flames. It would not have been much of a problem, except that when I want to do a step mash, the temps should move up to the next step as quickly as possible. This is mainly for the protein rest to keep the enzymes from breaking down all the proteins and leaving you with no head retention and a thin beer.

- Keep electronic copies of all your receipts that you receive by email. If you need an order number for a return, it’s much quicker to locate it in your email folders.

- No problem is overwhelming. Use the forums, especially HomeBrewTalk.com, or your local club forum if you have an active one. Search out guys in your club that have some expertise in your problem. Keep the troubleshooting basic. Start at the beginning, and work through the plumbing or schematic one piece at a time. It does you no good to do too many things at once because even if you do fix the problem, you have no idea what you did to fix it. If it reoccurs, you’ll have to work through the entire series of steps again.

How to Solve Common First-Day Brew Problems

Everything technically worked, but there are some pretty big problems nonetheless. Number one is the burners. I need to get a lot more BTUs from my burners.

I posted the question on HomeBrewTalk.com, and one of the gurus there, kladue, suggested drilling out the orifices to 3/32″ at least.

Another problem was my chilling setup. The 26-gallon pot was just too wide for the small immersion chiller. It didn’t help that I made a Belgian Wit and had Kumquats floating around which clogged the valve to the whirlpool.

I’m going to reconfigure for a Therminator I believe, but I’ll still use the ice water in my HLT either as a pre-chiller or to recirculate through the Therminator. I haven’t made a decision about this yet.

One last small problem was the fact that I put the temperature probe for my HLT too high. It works fine when heating 10 gallons of strike and sparges water.

However, once the strike water is transferred to the mash tun, the water level drops below the thermocouple and I can no longer measure the temperature of my sparge water, which needs to be raised from strike temp up to sparge temp.

So, I’ll have to put a cap on my 1/4″ Swagelok fitting and put another fitting much lower on my HLT. Not a big deal, just annoying.

The good news is that the Belgian Wit seems to have turned out fine. I ended up having to boil for two hours to evaporate enough wort to get close to my OG.

I was shooting for a 1.050 and got a 1.047. Not too bad for all the propane I had to use, but it’s cloudy. Maybe I’m on to something with the super low boil speed, but I’ll have to wait and see.

Lessons Learned From a RIMS Build

I’ve learned a lot since I started the RIMS build, which are as follows:

The more complicated the design of your RIMS brewing setup, the more complicated the problems and solutions. I went with some pretty advanced design features on this RIMS build. Some items I incorporated are:

- All stainless steel with Swagelok compression fittings.

- Honeywell dual gas valves with intermittent pilot lights.

- The Blichmann AutoSparge.

- The Blichmann HopBlocker.

- Inline carbon water filtration.

- Stainless steel pump heads.

- Clean in place (once the MT and Kettle have been dumped). Blichmann Therminator for chilling.

- Vinyl stick-on volume indicators for the sight-glass tubes on MT and HLT.

- Glass see-through lids to monitor inside the MT and HLT.

- Plumbing designed with stainless full-port ball valves to transfer fluids anywhere I want within my recirculating infusion mash system.

- Fully automatic temperature control on MT and HLT.

- Re-cycle cooling water through HLT. When ice is added, should be able to achieve lager pitching temps with the Blichmann Therminator, which saves water.

- Whirlpool concentrates hop particles in the center of the Kettle, making it easier for the Blichmann HopBlocker to filter wort.

- Upgradeable to Blichmann’s Boilermaker G2 20, 30, and 55-gallon MT and HLT.

- You need to make the lines on your brew stand large enough to prevent the pumps from cavitating. This happens when the pump gets starved for fluid. It sounds like a growling, metal-on-metal noise and isn’t pleasant. If the pump has a 1/2″ connection on the suction side, it’s there for a reason. You need your suction lines to be the same size as the suction connections designed by the pump manufacturer.

- The Honeywell gas valves are great for safety but aren’t designed to put out a lot of pressure. You may have to settle for safety over a shorter brew day. It may take some time to heat strike water, sparge water, and boil your wort due to the low-pressure requirements of the gas valves. I like the hurricane burners, though. They distribute the heat over a larger area and reduce the chances of scorching your wort. Even though there are sanitation requirements and some people have issues with the plate chillers, I found that the immersion chiller didn’t do the job in my design. On the day I brewed on my system, I used 4 bags of ice in the HLT and ended up stirring the wort by hand to accelerate the cooling. The Blichmann Therminator has proven to be a reliable solution and should get me down to pitching temps quickly.

- Before you drill holes in your kettles, think through your processes. I placed my HLT temperature probe too high on my HLT. When the strike water was transferred to the MT, on a 5-gallon batch, the temperature sensor was above the water line for the sparge water left in the HLT. Placing it lower should solve the problem, but since I didn’t plan on recirculating the sparge water while heating, may cause a problem of layering (ie. the water will show up as hotter near the bottom and will be cooler at the top.) Stirring by hand may be a simple solution.

- If you are lucky enough to get your recirculating infusion mash system up and running without any problems, great. But the rest of us should expect leaks (if the keggle fittings are not welded), bad design consequences (ie. the immersion chiller just wasn’t up to the task), mechanical problems (my regulator stepped down the propane too much at the source), etc. Be prepared to re-think your setup and have it flexible enough so that you can make changes quickly without any major problems.

- Be prepared for an all-stainless recirculating infusion mash system to be extremely expensive. After it’s all said and done, my system will have cost me around $6000 and the figure may go up once I add all the trips to town and all the small fittings. I even bought most of my Swagelok fittings in bulk on eBay and got some really great deals. If I’d paid full retail for everything, the system probably would have topped out at $9000. Don’t forget, I got the stand pre-made along with the hurricane burners and control panel (with everything ready except the wiring). To get the stand made by a competent welder with the quality of the materials in my stand would have cost roughly $2000 or more. It cost me $750 plus a trip from Lafayette, La to Pensacola, FL to pick it up.

UPDATE: I was having some priming problems with my pumps on my recirculating infusion mash system the last time I used my brewer. I was only pumping 1-Step Cleaner/Sanitizer through my lines, so the problems would have been multiplied with higher gravity wort.

I checked on my favorite forum, HomeBrewTalk.com. about solutions to the priming problems that others were having. On the link above, Walter and Hans from the March Pump Factory answered a lot of questions relating to their pumps.

I noticed several comments about having the discharge of the pump at the highest point of the pump housing to prevent air from getting trapped in the top of the housing and causing problems with priming.

I’d never heard of this before, but after thinking about it, it all makes sense. The trapped air wants to rise but the incoming fluid from a top-mounted suction keeps it trapped in the housing.

When a discharge is placed on the top side of the pump, however, the trapped air can then flow out with the discharging fluid and the pump gets primed more quickly. I called the factory and talked to Walter, in the engineering dept. (a very nice person who was glad to talk to homebrewers). He told me that a purge valve on the line will not help with the trapped air inside the housing, and thus will not help get your pump primed when you have them mounted this way.

So, I spent the better part of a day replumbing my pumps so that the suction was at the bottom and the discharge was at the top. I have yet to try it out but will update here when I do. Overall, it works a lot better now.

So, for all those that haven’t mounted your pumps yet, keep this in mind. It would have saved me a lot of work and trouble if I’d known about it sooner.